Publié le 4 novembre 2022 – Mis à jour le 4 novembre 2022

Author

Tatiana Budtovaa

a Mines ParisTech, CNRS, UMR 7635 Centre de Mise en Forme des Matériaux

In the view of the problems related to global climate changes, I would like to advocate for the responsible use of biomass for making sustainable materials. To do this, I will be using the principles of Green Chemistry, and I will apply them to materials science.Green Chemistry principles contain twelve general statements /1/ that should guide not only chemists, but also materials scientists, towards responsible and sustainable research and innovation. To say it simply: we, who are inventing new materials and processes, from molecules to the final product, must be reflective in our practice, and consider the environmental impact and consequences of our work and our processes. Below I will give some examples of Green Chemistry approaches, and I will also focus on the use of renewable feedstocks, which is the area of my research and is one of the principles of Green Chemistry.

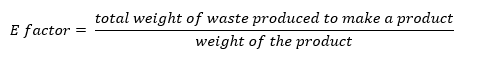

I would like to start with the main principles that should be considered whatever is the origin of starting matter, the way of making a molecule or material and its application. First, it is better to prevent/decrease waste than to treat or clean it up after it has been created. To estimate and quantify the “fraction of waste” (it is called “E-factor” /2/) produced during synthesis of a new matter or making a new product, a simple formula was suggested:

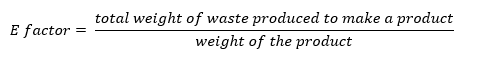

Another way to think about avoiding waste as much as possible is to consider “atom economy” /3/:

As matter is always related to energy, the processes should be energy efficient. This means that we should make every effort to enable the decrease of energy use. A basic example is to perform synthesis or make materials at ambient temperature and pressure, when possible.

Let us now focus on the use of the renewable feedstocks. The world around us relies on photosynthesis performed by Nature, which uses CO2, light and water and produces oxygen and sugars, the latter being the source of energy, chemicals and materials. Photosynthesis is a complex process that we, humans, cannot reproduce yet; fortunately, Nature is doing this continuously. For the time being, we use only about 3-4% of the biomass produced on the Earth.

It does not mean that we should exhaust the Nature’s Bounty, but we can make more use of natural resources and do so in a sustainable way. For example, we can use biomass to produce energy, chemicals and materials. Below I would like to give three examples related to the use of biomass: biorefinery approach, “old” matter for new materials and applications, and alternative biomass resources.

One of the best examples of sustainable approaches in using biomass is biorefinery. In its ideal form, this means “no waste” when converting biomass into energy and materials. For example, processing of lignocellulose biomass under the concept of biorefinery is gaining more and more attention /4/ and starts to be applied by pulp and paper companies. They become the producers not only of cellulose fibers for paper and textile, but also of fine chemicals, biofuels and new materials such as nanocellulose - for coating, cosmetics, pharmacology, biomedical, and materials-for-energy applications. Still, there are numerous challenges to overcome as lignocellulose is a complex and multicomponent composite material requiring specific processing routes due its recalcitrance; this requires new research paradigms and approaches, and new chemistry. The adequate application of biorefinery approach also needs the development of new infrastructure and logistics.

Interdisciplinary research can lead to the creation of new materials from well-known biomass for unanticipated and exciting applications. Here I would like to mention so-called bio-aerogels that are lightweight nanostructured fully bio-based materials /5/. For example, we used pectin, which is a gelling agent in food, for making aerogels that turned out to possess very low thermal conductivity and thus are extremely attractive for use in thermal insulation /6/. The same bio-aerogels can also be used as delivery matrices for controlled release of active substances for pharmaceutical and bio-medical applications /7/. Keeping in mind the principles of Green Chemistry, we are now working not only on the improvement of bio-aerogels’ performance, but also on consuming less energy in the processing stages.

When using biomass, one of the important issues is to avoid competition with food when producing materials or energy. Alternative sources should thus be considered, such as, for example, microalgae /8/. The combination of biotechnology, chemistry and materials science can lead to a rich and stimulating interdisciplinary collaboration resulting in materials and processes that make our lives not only greener, but better.

It should be noted that not all materials from biomass and processes of making them are sustainable. Biomass-based materials must not be “toxic” (in the large sense of the term) to the biosphere. Biodegradability must be considered. To evaluate material sustainability, life cycle assessment from “cradle to cradle” need to be performed: it makes an inventory of resources, energy used to make a product and generated waste, i.e. from gathering the raw matter to the end of product life and even to its “rebirth”.

To conclude, we are still at the beginning of a long way towards a sustainable future, and one of the solutions is a responsible use of the biomass. A lot of efforts and investments are still needed to stimulate the research and bridge the gap between the academia and industry. Our young generation needs a sustainable future and materials science should and can contribute to its development. I call on research colleagues, educators, and policy makers to redouble their efforts in promoting this broad agenda, as well as popularising and adhering to Green Chemistry principles more specifically.

References

- Anastas, P. T.; Warner, J. C. Green Chemistry: Theory and Practice, Oxford University Press: New York, 1998

- Sheldon, R.A. Atom utilisation, E factors and the catalytic solution C. R. Acad. Sci. Paris, Série IIc, Chimie/Chemistry 3 (2000) 541-551

- Trost, B. M. The Atom Economy-A Search for Synthetic Efficiency, Science (1991) 254, 1471-1477.

- Singh, N., Singhania, R. R., Nigam, R. S., Dong, C.-D., Patel, A. K., Puri, M. Global status of lignocellulosic biorefinery: Challenges and perspectives. Bioresource Technology (2022) 344, 126415

- Budtova, T., Antonio Aguilera, D., Beluns, S., Berglund, L., Chartier, C. Espinosa, E., Gaidukovs, S. Klimek‐Kopyra, A., Kmita, A., Lachowicz, D., Liebner, F., Platnieks, O., Rodríguez, A., Tinoco Navarro, L. K., Zou, F., Buwalda, S. J. Biorefinery Approach for Aerogels, Polymers (2020) 12, 2779

- Rudaz, C., Courson, R., Bonnet, L., Calas-Etienne, S., Sallee, H., Budtova, T. Aeropectin: fully biomass-based mechanically strong and thermal super-insulating aerogel, Biomacromolecules (2014) 15, 2188

- Groult, S., Buwalda, S., Budtova, T. Tuning bio-aerogel properties for controlling drug delivery. Part 2: Cellulose-pectin composite aerogels. Biomaterials Advances (2022) 135, 212732

- Tounsi, L., Hentati, F., Ben Hlima, H., Barkallah, M., Smaoui, S., Fendri, I., Michaud, M., Abdelkafi, S. Microalgae as feedstock for bioactive polysaccharides. Int. J. Biological Macromolecules (2022) 221, 1238